Paint Filling Machine – Accurate, Safe & Efficient Filling Solutions

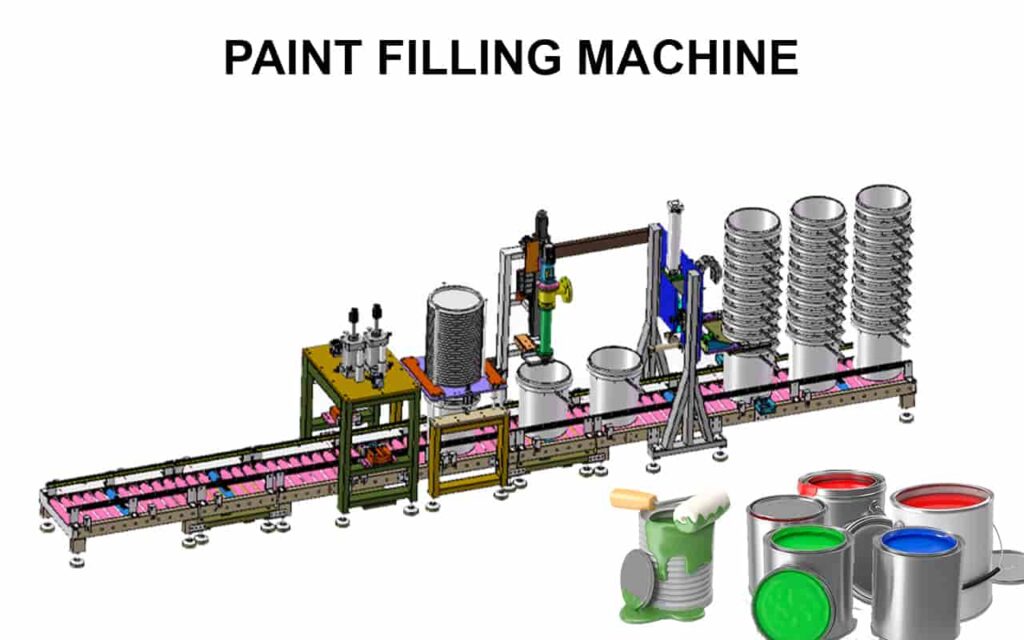

The Paint Filling Machine is designed for high-precision filling of water-based, oil-based, and solvent-based paints, as well as related liquids such as resin, glue, and latex.

Our automatic and semi-automatic paint filling machines provide fast, clean, and accurate filling for metal cans, plastic buckets, HDPE pails, and gallon containers, ensuring consistency and zero waste.

Built to handle 1L to 25L paint cans, as well as larger drums and IBC totes, this system is ideal for paint manufacturers seeking automation, accuracy, and safety in their production process.

Why Choose Our Paint Filling Machines?

| Feature | Description |

|---|---|

| High Accuracy | Weighing precision up to ±0.1% using gravimetric control. |

| Flexible Capacity | Suitable for 1L–25L cans, 20L pails, and 55-gallon drums. |

| Automation Level | Available in semi-automatic and fully automatic versions. |

| Explosion-Proof Design | ATEX-certified options for flammable coatings and solvents. |

| Material Compatibility | Stainless steel (SS304/316L) construction for durability and hygiene. |

| Optional Add-ons | Capping, lid pressing, labelling, and conveyor integration. |

What Is a Paint Filling Machine?

A paint filling machine is an industrial system that automates the process of filling liquid paints, varnishes, and coatings into containers.

Using weight-based (gravimetric) or volumetric control, it ensures each can, pail, or bucket is filled with exact accuracy, eliminating spillage and product loss.

Semi-automatic models are ideal for medium production lines, while fully automatic paint filling machines offer complete integration with capping, sealing, and labelling units.

Applications of Paint Filling Machines

Our paint filling equipment is used across multiple industries:

- 🏗️ Architectural Coatings – Emulsion, primer, wall paints, decorative coatings

- 🚗 Automotive Paints – Basecoat, clearcoat, metallic paint, varnish

- 🪵 Wood Finishes – Sealers, lacquers, wood varnishes

- 🏭 Industrial Paints – Epoxy, anti-corrosion, solvent-based coatings

- 🔬 Chemical Products – Resin, glue, dye, latex, adhesive materials

Semi-Automatic vs Automatic Paint Filling Machine

| Specification | Semi-Automatic Paint Filling Machine | Automatic Paint Filling Machine |

|---|---|---|

| Operation | Manual can placement, automatic filling | Fully automated, conveyor-fed |

| Production Scale | Medium volume | High-volume production |

| Accuracy | ±0.2% | ±0.1% |

| Safety | Optional ATEX explosion-proof version | Fully enclosed ATEX system |

| Maintenance | Simple and user-friendly | PLC-based self-diagnosis system |

| Integration | Optional conveyors, lid pressers | Complete packaging line with palletizer |

🪣 Compatible Containers

Our paint can filling machines are designed to handle all common packaging types:

- Metal Paint Cans – 1L to 5L

- Plastic Buckets & Pails – 5L to 25L

- HDPE Drums / Barrels – 30L to 55 gallons

- Gallon Containers – For adhesives, glues, and chemical paints

- Custom Containers – Compatible with unique shapes and lid styles

Market Trends: 20L Paint Filling Machines

The global market for 20L paint filling machines is growing rapidly at 4–6% CAGR, driven by rising demand in construction, automotive refinishing, and industrial coatings.

Automation, digital control (PLC + HMI), and eco-friendly production are now industry standards.

Manufacturers are adopting:

- IIoT-enabled control systems

- Data logging for traceability

- CIP (Clean-in-Place) automatic cleaning

- Energy-efficient weighing valves

Regions such as Asia-Pacific (China, India, SE Asia) dominate production, while Europe and North America lead in innovation and safety compliance.

🔧 Technical Highlights

- Gravimetric control with dual-speed filling (coarse + fine)

- Explosion-proof electrical cabinet (ExdII BT6)

- PLC: Mitsubishi Japan / Schneider France components

- Adjustable nozzles for 1L–25L cans

- Anti-drip stainless steel filling heads

- Optional automatic lid pressing & sealing system

💡 Advantages of Our Paint Filling Equipment

- ✅ Zero Wastage – Precision filling reduces overfill losses

- ✅ Labour Efficient – One operator can handle multiple lines

- ✅ Hygienic Design – Stainless steel build for easy cleaning

- ✅ Energy Efficient – Smart filling valves save compressed air and power

- ✅ Explosion-Proof – Certified for solvent-based paints

- ✅ Scalable System – Upgrade from semi-automatic to full automation anytime

🏭 Industry Use Cases

- Paint & Coating Manufacturers – Decorative and industrial coatings

- Adhesive & Glue Producers – Resin, latex, and polymer-based adhesives

- Chemical Industries – Solvents, dyes, and pigments

- Construction Material Plants – Waterproof coatings and sealants

- OEM Private Label Manufacturers – Custom packaging for paint brands

Popular Related Machines

- Automatic Paint Filling Machine – For high-volume filling

- Semi-Automatic Paint Filling Machine – Compact and cost-effective

- Paint Packaging Machine – For sealing, capping, and labelling

- Gallon Filling Machine – For oil, resin, and latex

- Chemical Filling Machine – For viscous or corrosive materials

- Pail Filler Machine – Designed for large bucket paint packaging

Contact Us for a Custom Paint Filling Solution

Looking for a paint filling machine that matches your production needs?

Our engineers can customise automatic and semi-automatic paint filling systems for your paint viscosity, container size, and speed requirements.

📍 Location: No. 409, Xintuo Road, Songjiang District, Shanghai, China

📞 WhatsApp / WeChat: +88 01940214915