Unlock precision and automation with our advanced automatic IBC filling machines, designed to handle a wide range of liquids like engine oils, lubricants, chemicals, and edible oils. Whether you need IBC filling equipment or tote filling machines, our solutions offer high-speed, precise, and efficient filling systems that reduce operational costs and increase production output.

What is an Automatic IBC Filling Machine?

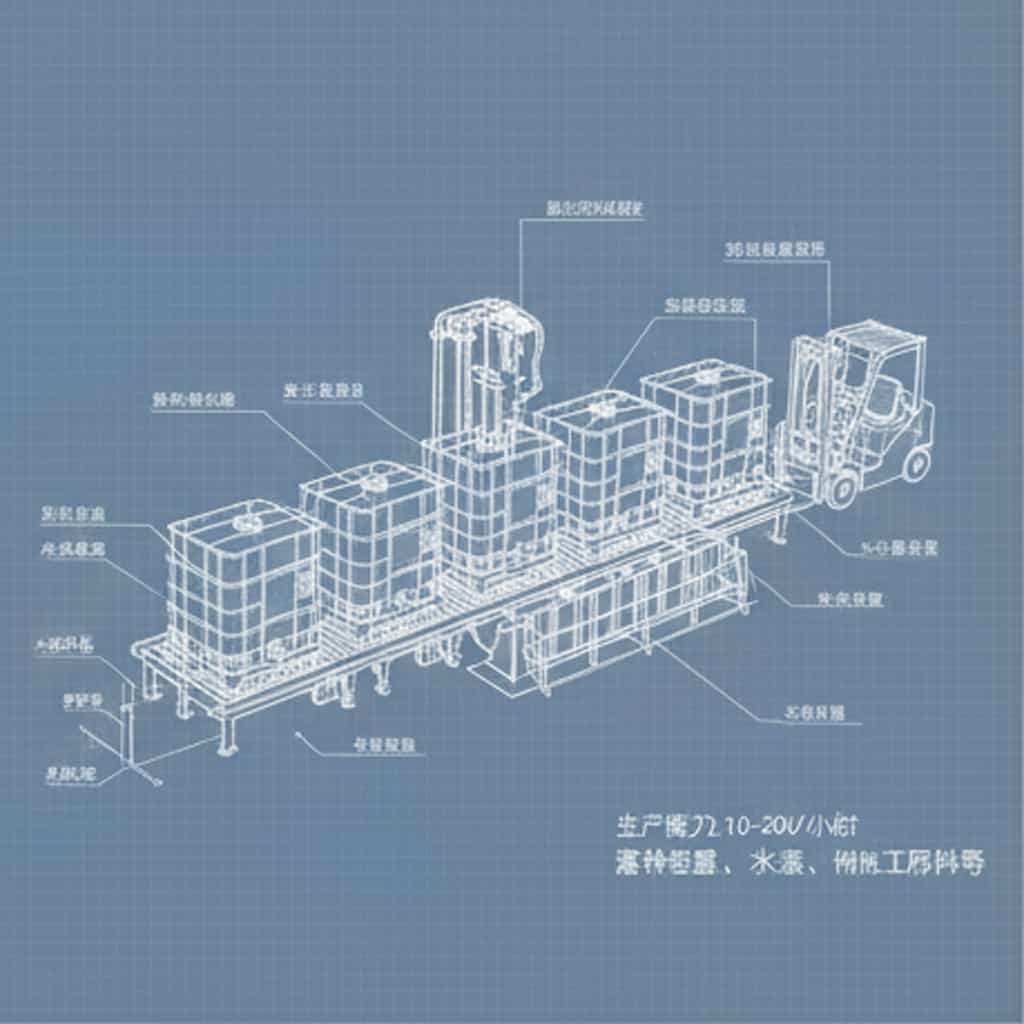

An IBC filling machine automates the filling process for Intermediate Bulk Containers (IBC totes), ensuring fast and accurate dispensing of liquids like oils, chemicals, and food-grade products. These machines are crucial for industries that require high precision and efficiency, such as chemical filling, oil production, and food processing.

With a competitive search volume and medium competition, IBC filling equipment is increasingly in demand as businesses seek to optimize their bulk liquid filling processes. Our systems are ideal for IBC filling machines, tote filling equipment, and other bulk containers, offering a cost-effective solution for businesses looking to scale production without the overhead of fully automated systems.

Why Choose Our Automatic IBC Filling Equipment?

- High Precision and Accuracy:

Achieve ±0.2% to ±0.5% accuracy, ideal for high-value products like engine oils, lubricants, and chemicals. This precision minimizes waste, ensuring the most accurate fills for your containers. - Fully Automated Operation:

Our automatic filling systems provide seamless operation, from container placement to filling and nozzle retraction, minimizing the need for manual labor and maximizing throughput. - Cost-Effective Solutions:

With medium competition and an increasing search volume for IBC filling machines and tote filling machines, businesses are looking for scalable and cost-effective filling solutions. Our systems provide automated efficiency without the significant upfront cost of fully robotic systems. - Scalable for Multiple Applications:

Whether you’re filling viscous oils, flammable chemicals, or food-grade liquids, our systems are highly adaptable and customizable, ensuring consistent and reliable fills.

Key Features of Automatic IBC & Tote Filling Machines

| Feature | Description | Benefit |

|---|---|---|

| Filling Accuracy | ±0.2% to ±0.5% (depending on product) | High-precision filling reduces waste and ensures compliance. |

| Filling Speed | 30–50 200L drums/hour, 20-30 IBCs/hour | Increased throughput, ideal for large-scale operations. |

| Load Cells | Mettler-Toledo for accurate, weight-based filling | Accurate fills that minimize overfilling, particularly for oil, lubricants, and chemicals. |

| PLC Control System | Siemens PLC with touch screen interface for easy operation and diagnostics | Simplifies operations, tracks data, and allows easy recipe management. |

| Safety Features | Explosion-proof protection, electrostatic grounding, emergency stop switches | Protects operators and reduces environmental risks. |

| Material Compatibility | 304 stainless steel and food-grade materials for handling both chemicals and edible oils | Safe for a wide variety of liquids, ensuring high safety standards. |

How Our Automatic IBC & Tote Filling Machines Work

- Container Placement:

The IBC tote or drum is placed on the conveyor system, where sensors confirm proper alignment before the filling begins. - Filling Process:

Using Mettler-Toledo load cells, the system accurately weighs the liquid during the filling process to ensure the target weight is reached with ±0.2% to ±0.5% accuracy. - Nozzle Action:

The nozzle automatically adjusts to fill from the bottom, ensuring minimal foam formation and preventing overfilling. - Post-Filling Nitrogen Injection:

For sensitive products like fish oil, a nitrogen injection system is used to prevent oxidation after filling. - Data Collection:

Real-time data collection ensures traceability for each batch, including batch numbers, operator IDs, filling times, and production efficiency.

Benefits of Automatic IBC & Tote Filling Machines

- Cost-Effective Automation:

Achieve automated filling with minimal labor costs, ideal for businesses scaling their production of engine oils, lubricants, chemicals, and other bulk liquids. - Increased Throughput:

Fill IBC totes, drums, and containers faster, improving production rates and reducing labor time. - Enhanced Safety:

The automated system reduces manual intervention, lowering the risk of exposure to hazardous liquids such as chemicals and flammable oils. - Data-Driven Insights:

Integrated PLC control systems collect valuable production data to track filling accuracy, cycle times, and machine performance, helping optimize your production process.

Ideal Applications for Automatic IBC & Tote Filling Machines

- Oil Industry:

Fill a variety of oils, including lubricants, motor oils, and edible oils, with high accuracy, ensuring consistent product quality and reducing waste. - Chemical Industry:

Safely handle and fill chemicals, pesticides, acids, and bleaches, offering reliable operation even with corrosive or volatile liquids. - Food & Beverage:

Fill edible oils, sauces, and other liquid food products with precision, complying with food safety standards. - Pharmaceuticals:

Ensure traceability and accuracy for pharmaceutical liquids, bio-products, and other regulated substances.

Why Choose Us for Your Automatic IBC & Tote Filling Solutions?

- Customizable Solutions:

Our machines are tailored to handle a variety of liquids, from viscous oils to chemicals and food-grade liquids, ensuring maximum compatibility with your products. - Comprehensive Support:

From installation to ongoing maintenance, we provide full-service support to ensure your system operates at peak efficiency. - Industry Expertise:

With years of experience in filling systems for oil, chemicals, and food, we understand the unique challenges of filling bulk liquids and offer solutions that optimize your operations.

Conclusion: Revolutionize Your Filling Process with Our Automatic IBC & Tote Filling Machines

Investing in an automatic IBC & tote filling machine offers significant benefits, from precision and speed to cost savings. Whether you’re filling chemicals, oils, or edible liquids, our solutions provide the accuracy and reliability required to streamline your operations.

Contact us today to explore how our automatic IBC & tote filling systems can enhance your operations and drive growth.